Alina Pranovich, Morten Rieger Hannemose, Janus Nørtoft Jensen, Duc Minh Tran, Henrik Aanæs, Sasan Gooran, Daniel Nyström, Jeppe Revall Frisvad

Sensors 24(21), Article 7025. October 2024. [abstract]

Alina Pranovich 1,2, Morten Rieger Hannemose 1, Janus Nørtoft Jensen 1,3, Duc Minh Tran 1, Henrik Aanæs 3, Sasan Gooran 2, Daniel Nyström 2, and Jeppe Revall Frisvad 1

| 1 |

Department of Applied Mathematics and Computer Science, Technical University of Denmark, 2800 Kongens Lyngby, Denmark |

| 2 | Department of Science and Technology, Linköping University, 602 33 Norrköping, Sweden |

| 3 | 3Shape, 1059 Copenhagen, Denmark |

Abstract

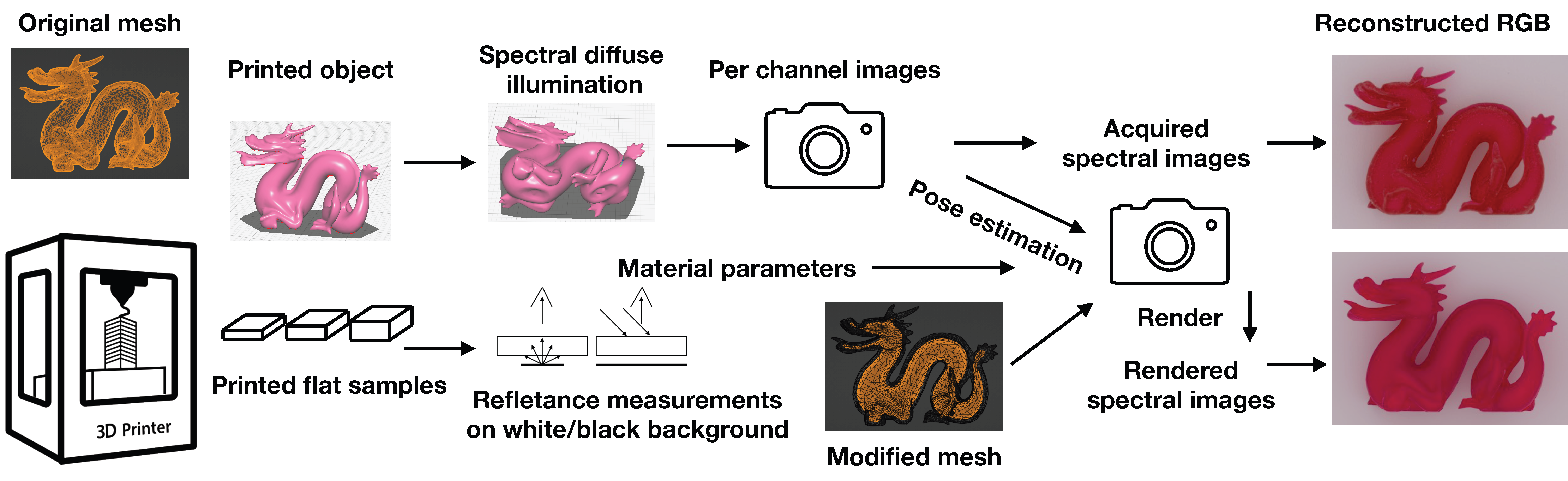

The conventional approach to appearance prediction for 3D printed parts is to print a thin slab of material and measure its reflectance or transmittance with a spectrophotometer. Reflectance works for opaque printing materials. Transmittance works for transparent printing materials. However, the conventional approach does not work convincingly for translucent materials. For these, we need to separate scattering and absorption. We suggest printing a collection of thin slabs of different thicknesses and using these in a spectrophotometer to obtain the scattering and absorption properties of the material. A model is fitted to the measured data in order to estimate the scattering and absorption properties. To this end, we compare the use of Monte Carlo light transport simulation and the use of an analytic model that we developed from the theory of radiative transfer in plane-parallel media. We assess the predictive capabilities of our method through a multispectral photo-render comparison based on the estimated optical properties.

Keywords: additive manufacturing; appearance modeling; digital twin; model validation; spectral optical properties; radiative transfer; soft proofing

Click the thumbnail to follow the DOI link to the publishers website. Click the title to get the pdf.

| Digitizing the appearance of 3D printing materials using a spectrophotometer Alina Pranovich, Morten Rieger Hannemose, Janus Nørtoft Jensen, Duc Minh Tran, Henrik Aanæs, Sasan Gooran, Daniel Nyström, Jeppe Revall Frisvad Sensors 24(21), Article 7025. October 2024. [abstract] |

Graphical Abstract